Uncovering the Diverse Types and makes use of of Rubber Keypads in the Modern Technology Landscape Today

Rubber keypads have established themselves as vital elements in various technological applications. Their adaptability makes them appropriate for customer electronics, commercial devices, and medical gadgets. As these keypads continue to advance, new modification choices and design trends arise. This motivates a more detailed exam of their advantages and making procedures. Recognizing these elements may disclose why rubber keypads stay a recommended selection in the innovation landscape. What exists in advance for this functional element?

Overview of Rubber Keypads

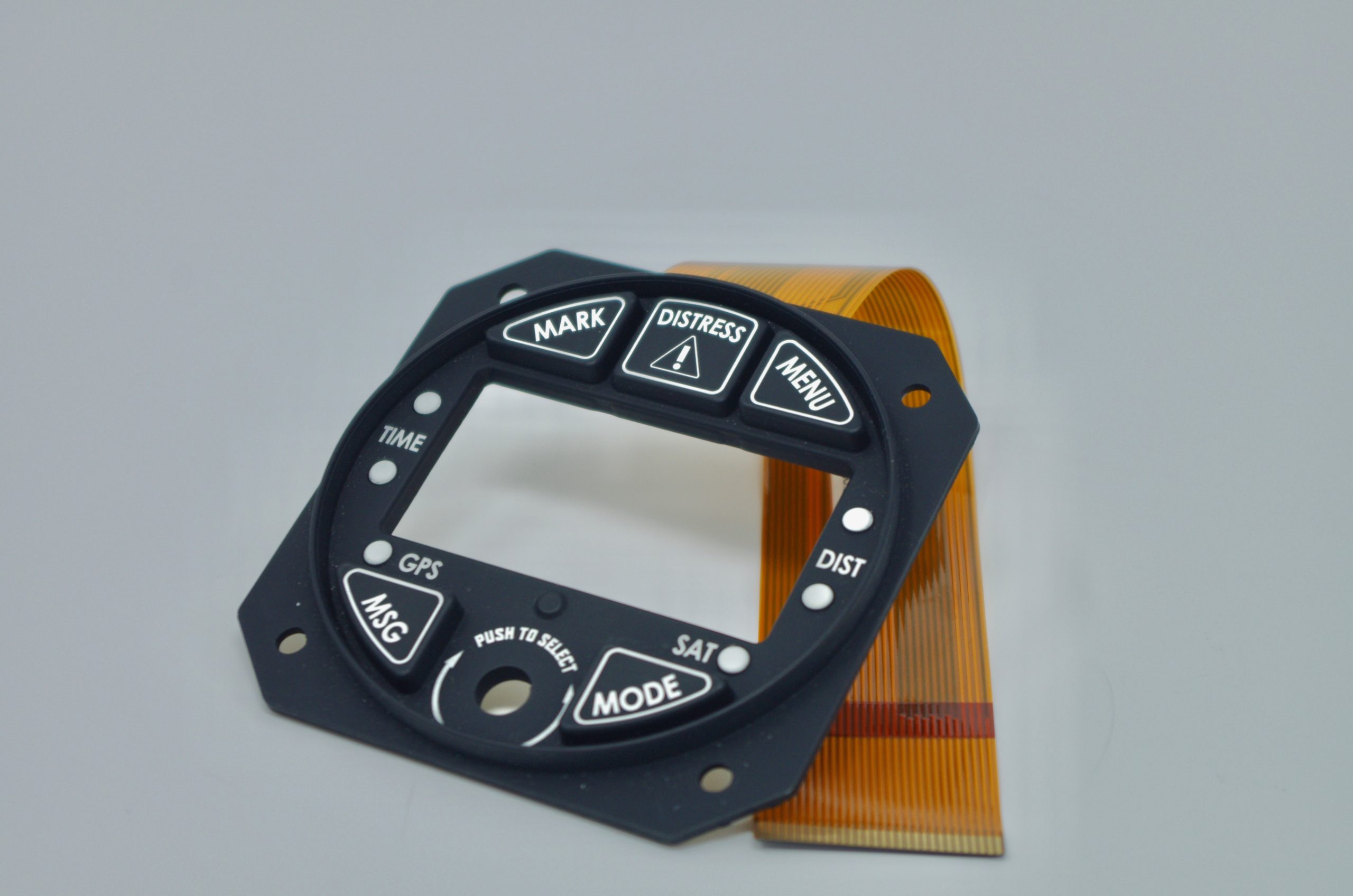

Rubber keypads work as a basic component in various digital gadgets, offering a tactile interface for individual communication. These keypads are generally made from silicone or rubber products, which supply versatility and resilience. Their design typically includes raised letters or symbols, boosting use by allowing users to feel the secrets - Rubber Keypads. Rubber keypads are resistant to dirt, dampness, and put on, making them ideal for demanding environments

They can be personalized regarding size, shape, and color, enabling producers to create special interfaces customized to specific items. The production process usually involves methods such as molding and printing, guaranteeing top quality result. Therefore, rubber keypads not just boost capability but additionally add to the overall aesthetic appeals of the gadget. With these attributes, rubber keypads stay a popular choice for both customers and producers, stressing their significance in the modern technology landscape.

Typical Applications in Consumer Electronic Devices

While lots of digital devices rely upon touchscreens for user communication, rubber keypads remain to play a necessary duty in consumer electronic devices. These keypads are commonly used in gadgets such as remotes, gaming controllers, and home appliances, where responsive comments enhances customer experience. Their resilience and resistance to put on make them ideal for devices frequently subjected to hefty usage.

Rubber keypads are additionally preferred in mobile gadgets and mobile phones, where compact layouts necessitate responsive and trusted input techniques. The capability to tailor the form and appearance of rubber keypads allows producers to create special layouts that interest customers. In addition, the soft touch of rubber provides convenience during prolonged usage, making these keypads a recommended choice for devices calling for prolonged interaction. On the whole, rubber keypads remain a vital part in the consumer electronic devices landscape, combining functionality with easy to use features.

Function in Industrial and Medical Devices

Rubber keypads play an important duty in both medical and industrial tools, offering longevity and integrity popular environments. In commercial settings, they are typically used in control panels and equipment, enhancing driver communication with facility systems. Likewise, in the medical area, rubber keypads promote straightforward interfaces for tools that need precision and hygiene.

Industrial Tools Applications

Keypads play an essential role in the functionality and customer experience of clinical and industrial equipment. In industrial settings, rubber keypads supply a durable interface for machinery and control systems, allowing drivers to conveniently input commands and adjust setups. Their resistance to dust, wetness, and chemicals assurances dependability under rough problems typical of factories and making plants. In addition, the tactile feedback offered by rubber keypads boosts user interaction, lowering the probability of input errors. Along with traditional equipment, these keypads are indispensable in automated robotics and systems, where accuracy is extremely important. The versatility of rubber keypads in numerous commercial applications emphasizes their value in enhancing operational effectiveness and guaranteeing safety and security in complex settings.

Medical Gadget Combination

As medical devices significantly call for straightforward interfaces, the integration of rubber keypads has ended up being vital in making certain reliable communication between health care professionals and devices. These keypads offer tactile comments, promoting user-friendly operation even in high-pressure settings. Their longevity and resistance to severe cleaning agents make them perfect for clinical settings, where health and durability are crucial. Furthermore, rubber keypads can be customized to include numerous forms, dimensions, and shades, enhancing aesthetic recognition and availability for individuals. This adaptability enables the production of specialized controls customized to specific medical functions, boosting total efficiency. Subsequently, the duty of rubber keypads in medical gadget assimilation not just improves functionality but likewise promotes person safety and operational dependability in healthcare environments.

Customization Options and Design Trends

Current layout patterns highlight minimalism and functional designs, focusing on individual convenience and user-friendly interaction. Custom logo designs and branding can be incorporated right into keypads, permitting business to maintain a cohesive brand identity across their items. In addition, improvements in producing techniques, such as silicone molding, have made it simpler to achieve intricate styles and individualized layouts.

Benefits of Rubber Keypads Over Other Types

Rubber keypads are likewise understood for their toughness and resistance to environmental variables. They can withstand moisture, temperature level, and dirt fluctuations, making them optimal for industrial or outdoor setups. Additionally, rubber keypads are commonly quieter than their plastic or metal equivalents, lowering environmental pollution in shared environments.

Additionally, the cost-effectiveness of rubber keypads makes them an attractive choice for makers. Their light-weight nature adds to lower delivery expenses, while their customizable styles accommodate details branding needs. On the whole, rubber keypads represent a functional and dependable solution in the technology landscape.

Production Techniques for Top Quality and Toughness

In the manufacturing of rubber keypads, the option of appropriate materials and molding procedures plays a crucial role in identifying general top quality and durability. Various molding techniques, such as compression and injection molding, considerably influence the final product's performance. Recognizing these factors is essential for achieving ideal outcomes in rubber keypad manufacturing.

Molding Procedures Explained

A variety of molding processes play an essential duty in the manufacturing of rubber keypads, making certain both high quality and longevity. One of the most common methods consist of compression molding, transfer molding, and shot molding. Compression molding includes positioning rubber in a heated mold, where warmth and pressure shape it right into the preferred kind. Transfer molding permits more accurate control over material flow and appropriates for complicated styles (Rubber Keypads). Injection molding, known for its speed and effectiveness, injects liquified rubber into a mold under high stress, generating high-volume parts with consistent top quality. Each technique uses distinct benefits, influencing aspects such as manufacturing find here cost, speed, and layout flexibility, inevitably affecting the efficiency and life expectancy of rubber keypads in different applications

Product Selection Importance

Material choice plays an important function in the manufacturing of rubber keypads, directly influencing their performance and sturdiness. The selection of this page rubber substances, such as silicone or polyurethane, effects responsive responses, resistance to put on, and environmental toughness. High-quality products guarantee that keypads can stand up to considerable use, maintaining their capability in time. Furthermore, the formula of rubber impacts its resistance to temperature variations and exposure to chemicals, which are essential for devices in different atmospheres. Employing sophisticated manufacturing methods, such as compression or shot molding, further boosts the architectural stability of keypads. Eventually, cautious material option and manufacturing procedures add considerably to the total top quality, durability, and customer fulfillment of rubber keypads in today's modern technology landscape.

Future Trends in Rubber Keypad Modern Technology

As innovation remains to advance, the future of rubber keypad innovation appears promising, with innovations poised to improve capability and customer experience. One significant pattern is the assimilation of touch-sensitive technology, enabling capacitive comments that mimics the feeling of typical switches while supplying boosted responsiveness. Furthermore, the development of antimicrobial materials is likely to obtain traction, dealing with hygiene issues in common and public devices.

In addition, customization options are expected to expand, allowing customers to individualize crucial layouts and tactile responses, thus satisfying varied demands. The consolidation of clever technology, such as connection attributes, might additionally arise, enabling rubber keypads to engage with other gadgets perfectly. As makers concentrate on sustainability, eco-friendly products are anticipated to become more common, straightening with global ecological objectives. Overall, these fads promise to reinvent rubber keypads, making them more functional, straightforward, and ecologically aware in the technology landscape.

Frequently Asked Questions

Just How Do Rubber Keypads Compare in Expense to Other Keypad Types?

Rubber keypads generally offer an affordable remedy contrasted to various other keypad types, such as membrane layer or mechanical options. Their reduced manufacturing expenditures and durability make them an appealing selection for numerous applications in modern technology.

What Are the Ecological Effects of Rubber Keypad Manufacturing?

The ecological effects of rubber keypad manufacturing consist of resource exhaustion, power consumption, and contamination from making processes. Furthermore, inappropriate disposal can bring about plastic waste, adding to ecological deterioration and harming ecosystems if not handled sensibly.

Can Rubber Keypads Be Utilized Outdoors?

Rubber keypads can be used outdoors because of their sturdiness and resistance to weather aspects. Their longevity may depend on the top quality of materials utilized and the certain environmental problems they are subjected to.

What Maintenance Is Required for Rubber Keypads?

Rubber keypads need routine cleansing to remove dust and particles, regular examination for wear and tear, and defense from severe temperatures. Making certain correct storage space problems can expand their life-span and keep capability gradually.

Just How Do Rubber Keypads Perform in Extreme Temperatures?

Rubber keypads usually keep capability in extreme temperature levels, exhibiting strength to both warmth and cold. Nevertheless, extended direct exposure might cause product destruction, influencing their tactile reaction and total performance in harsh atmospheres.

Rubber keypads offer as an essential look these up component in different electronic devices, supplying a responsive interface for user interaction. While lots of electronic tools depend on touchscreens for user interaction, rubber keypads continue to play an important function in customer electronics. In addition, the soft touch of rubber gives convenience during extended use, making these keypads a favored choice for devices requiring prolonged communication. Despite the expanding range of keypad materials available, rubber keypads use distinct advantages that make them a preferred option in many applications. Rubber keypads normally offer a cost-efficient remedy contrasted to other keypad types, such as membrane or mechanical alternatives.